Business

Panasonic, The Lumbering Tech Massive That Makes Cameras.

Published

4 years agoon

The only way to endure — it seems — is to have a substantial industry share (like Canon) or participate in a much larger company (like Fujifilm). Or, indeed, equally (like Sony). Panasonic comes to the latter camp, a stalwart of the electronic time that continues to drive out new models. So what is their strategy, and where is it going?

A Breakdown of the Business

Panasonic, known as Matsushita until 2008, is not just a small business, with a turnover of ~$65 thousand (in 2024) and hiring some 260,000 people. Their primary emphasis is on house appliances, such as electronic devices, production in large volumes equipment such as home appliances, refrigeration, displays (projectors and TVs), DVDs, PCs, and cameras. Nevertheless, Panasonic also styles and sells to the consultant avionics, automotive, and professional markets.

Their cameras fall within the much larger Devices Team, which makes up 37% of income, while different large divisions include Living Alternatives (22%), Automotive (20%), and Professional (19%). For Panasonic, 2024 found a slight lowering of revenue (11%) and running gain (12%), even though the Devices Team found a smaller decline in revenue (4%) but an increase in running growth (8%).\

Beyond this standard overarching view of the company, it’s nearly impossible to get any meaningful information on Panasonic’s cameras; if you appear through their 2024 financial record, cameras aren’t also stated, while disaggregating their revenue is difficult as the organization does not talk about cameras (let alone revenue volumes!) and the only different primary full is from the BCN Awards Data. Panasonic does not function in the three principal classes (mirrorless, DSLR, integrated), although it steamrollered the video camera prize, taking 43.6% of revenue, followed closely by Sony (26.3%) and DJI (11.2%). Nevertheless, this is not something group for CIPA, so we do not know how many worldwide deliveries they represent.

Panasonic’s corporate headquarters in Kadoma, Osaka, Japan. Photo by Pokarin and licensed under CC BY-SA 4.0.

The sole different new knowledge position we’ve is from the Techno System Study advertising record for 2020 (as reported by Fuji Rumors), which confirms worldwide camera deliveries at 8.9 million devices with the following industry share: Cannon (47.9%), Sony (22.1%), Nikon (13.7%), Fuji (5.6%), and Panasonic (4.4%).

This combines mirrorless, DSLR, and incorporated cameras; the record then centers around the mirrorless phase, with industry shares adjusting to Sony (35.7%), Cannon (32.6%), Fuji (11.8%), Nikon (8.0%), Olympus (6.4%), and Panasonic (5.5%). With worldwide shipping knowledge from CIPA, Panasonic’s share equates to about 157,000 devices, only hair’s thickness straight back from Olympus and Nikon.

Wherever Has Panasonic Come From?

Panasonic’s camera company is primarily predicated on electronic innovation, though, much like Sony, it was producing movie cameras back in the 1980s and knew contact design. The dust-covered record of movie cameras could even make some versions, though they were base corner, point-and-click, affairs like the C-225EF.

Since the 1990s evolved, it steadily introduced more superior technology such as autofocus and super-zooms. At once, it was also developing early compact electronic versions like the PV-DC1000 and NV-DCF1 (both in 1997). Nevertheless, the pivot to electronic found a step-change in its production, essentially created upon the corporate relationships it forged—two stick out which have stood the check of time: Leica and Olympus.

Panasonic was presumably the maker of the 1995 Leica Minilux before the building blocks of the Lumix group of compact cameras in 2001, for which Leica allowed the usage of their contact constructions but left the style and production (subject to approval) to Panasonic. In Inturn, Panasonic focused upon camera electronics. This is similar to Leica’s relationship with Minolta in the 1970s, but this time around, it wanted to reforge itself because the electronic time dawned.

The LC5 and F7 were the very first fruits of the labor and noted a step up from Panasonic’s last promotions; it was the best relationship, at the best time, in the same way, digital camera revenue exploded.

Panasonic was still not positioned because it attempted to reach out distinctively from Nikon, Canon, and Sony (which had only bought the well-established Minolta). Olympus offered an alternate way through their Four Thirds System relationship with Kodak. Olympus had singularly failed to pivot to a digital SLR from their successful line of OM movie cameras. The Four-Thirds was an additional mouthful at the apple, except this time around performing something purposely different to different suppliers that were not APS-C or w

The Panasonic L1 DSLR. Photo by Rama and licensed under CC BY-SA 2.0 FR.

hole frame.

The E-1 was Olympus’s first providing that introduced a brand new alarm measurement and contact install, starting a new process from scratch. Kodak was now in the sunset of the electronic time and would soon diminish to obscurity. However, it equipped the first receptors before Panasonic stuffed the production space in later Olympus models. Ultimately, only Panasonic (and, as a result, Leica) and Olympus built camera figures for the Four-Thirds ecosystem.

The E-1 was a revolutionary fail; the 2x plant factor of the Four Thirds specification offered cameras achieve and, with small files, potentially speed. Additionally, it designed they could be equally smaller and lighter. Olympus produced the E-1 for media and activities photographers, but fundamentally it was not very priced and had somewhat gradual firing speeds and AF compared to Canon and Nikon.

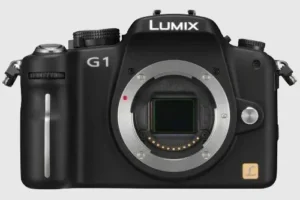

The Panasonic G1 was the first Micro Four Thirds system camera body.

Panasonic, however, had joined the party and produced their first-ever DSLR in the shape of the L1 in 2006. The L1 and their successor, the L10, were Panasonic’s only Four-Thirds cameras because the brand pushed forward with developing the Micro Four Thirds (MFT) system. Who knows who created the idea, but perhaps Panasonic’s movie qualifications were the driver behind removing the mirror box; this offered more video-like efficiency and saved space and weight. However, the disadvantage was that it now counted on contrast focusing, a strategy in their infancy.

Panasonic was the first to ever the production punch with the release of the G1 in 2008, followed — in time — by the Olympus Pen E-P1. While it would get Olympus till 2012 with the freedom of the OM-D E5 to innovate, Panasonic had nailed their motives to the mast from time one. The video was master, and there are a robust industry of amateur (and not amateur) videographers wanting the product.

The Panasonic LC5 (left) and F7 (right) digital cameras.

Panasonic had healthy revenue from time one and had the central spot in BCN mirrorless at 38.7% in 2011 when the group first appeared (probably from 2008). It was not before the release of the OM-D E-M5 in 2012 that Olympus eventually overtook it. Possibly Panasonic found the writing on the wall at this point, whether it was necessary to promote equally small and large receptors or that Olympus was entirely devoted to MFT. However, it decided to produce full-frame versions in the shape of the S1 and S1R in 2019. This demonstrably came from their relationship with Leica; the L-mount first appeared on Leica’s 2014 Leica T and is an entirely contemporary mirrorless install created for full-frame.

The Olympus E-1 was the first Four Thirds camera.

Was this part of Panasonic’s strategy, did Leica need Panasonic to generate a full-frame design as part of their formal alliance, or was it the opportunity that showed itself? Regardless of the reason, Panasonic now sees itself with an enviable range of MFT cameras that can be compact and exceptionally proficient at the video. They’re with a high-performance full-frame camera that shares a heritage with Leica and has an increasing range of native lenses.

There’s now equal width and degree to their offerings

Does Panasonic Have an Intelligent Long-Term Strategy?

The bigger question is this: does Panasonic — from bottom-of-the-bin movie cameras to high-performance full-frame cameras — have a clever long-term strategy? Or are cameras simply a corporate plaything reinforced and cross-subsidized by the more prominent company?

Firstly, Panasonic does not have a long camera heritage like Canon or Nikon; there is apparent pleasure in their services and products. However, it is not the ethnic cornerstone of the business.

The Panasonic S1R (left) and S1 (right) full-frame mirrorless cameras.

Secondly, it’s been constant in their quest for accomplishment and industry share from their early alliance with Leica.

Additionally, it hasn’t been scared to innovate within the restrictions of its former partners. Cannon, Nikon, and Sony have all been singularly focused on their methods and, in their very own ways, traditional (although perhaps less so with Sony).

Have developments in Four Thirds, MFT, and full-frame only been an incident of being in the best at the best time, or has Panasonic been gradually building width and degree as capacity and capacity have improved? It was recently devoted to continuous the width of their MFT offerings.

Turning this line of thinking on their head, was full-frame a “done deal” right from the start? Was there always a schedule to generate a large alarm design with Leica as equal organizations created in conjunction? Are we viewing the fruits of the strategy even as we enter the 2020s?

Is Panasonic going to boost their industry presence, building out their full-frame selection as part of the L-Mount Alliance with Leica and Sigma? Or is all we are viewing a haphazard method of their product range development? If the L-Mount is not successful, can it pull the product selection to keep its focus on Micro Four Thirds?

Related Posts:

Hi, my name is Nebojša, and I've been involved in digital marketing for over 15 years. I've written for various websites, covering a wide range of topics. I'm particularly interested in subjects like technology, gaming, app development, and I also have a passion for automobiles. Additionally, I work on SEO optimization. In my free time, I enjoy reading, walking, traveling and spending time with my wife and daughter.

You may like

In today’s rapidly shifting economic landscape, businesses often find themselves navigating uncharted waters. Financial control is more critical than ever, and for many organizations, the presence of an Interim Chief Financial Officer (CFO) can be a transformative catalyst.

These seasoned professionals bring a wealth of experience, ready to tackle the myriad challenges that arise when fiscal uncertainty looms large. An Interim CFO doesn’t just step in to fill a gap; they strategically reshape financial frameworks, implement robust controls, and establish rigorous reporting standards.

Whether it’s during times of transition, crisis management, or growth initiatives, their insights and expertise can mean the difference between stability and chaos. This article delves into the pivotal role Interim CFOs play in enhancing financial governance and ensuring that organizations emerge stronger from turbulent periods.

Assessing Financial Health

Source: bridgepointconsulting.com

Assessing financial health is a critical undertaking that interim CFOs approach with both rigor and insight. They dive deep into the numbers, examining everything from cash flow to profitability margins, understanding that each figure tells a story. This analysis goes beyond mere data; it weaves together trends, forecasts, and historical performance to create a comprehensive picture of the organization’s fiscal vitality.

Are there hidden costs lurking in operational expenses? Is revenue being maximized? These questions demand answers, and interim CFOs are adept at uncovering the nuances within financial statements. Their keen eye for detail allows them to identify both strengths and weaknesses within the financial framework, paving the way for strategic adjustments that can enhance both stability and growth.

In this dance of digits, agility is essential—because in the world of finance, timing can be everything.

Implementing Robust Financial Controls

Source: news24.com

Implementing robust financial controls is a critical step that interim CFOs take to fortify an organization\’s fiscal health. These controls serve as a safeguard, ensuring that financial processes are not only efficient but also transparent.

Picture a web of interconnected policies and procedures—document reviews, approval processes, and compliance checks—all woven together to minimize risk and prevent errors. An interim CFO often steps into a firm with fresh eyes, identifying gaps that may have eluded others for years.

They might introduce sophisticated auditing techniques while also streamlining simple tasks to foster a culture of accountability. By engaging teams in this process, they not only enhance accuracy but also empower staff to take ownership of their roles within the financial ecosystem.

In this intricate landscape, a strong framework of financial controls acts as both a compass and a shield, guiding decisions while protecting the organization from unforeseen pitfalls.

Enhancing Budgeting and Forecasting

Source: onboardingofficers.co.uk

Interim CFOs bring a fresh perspective to the often mundane world of budgeting and forecasting, transforming it into a dynamic tool for strategic insight. With their diverse experiences across industries, these financial leaders adeptly dissect existing budgets, uncoupling inefficient patterns and illuminating overlooked opportunities.

They introduce sophisticated modeling techniques that integrate historical data with real-time market trends, enabling organizations to anticipate shifts and respond with agility. Moreover, by fostering collaboration between departments, they craft a more inclusive budgeting process, one that aligns financial goals with operational realities.

The result? A robust financial roadmap that not only guides the present but also charts a course toward future growth, empowering businesses to navigate uncertainty with confidence.

Conclusion

In conclusion, interim CFOs play a pivotal role in enhancing financial control within organizations by bringing specialized expertise, fresh perspectives, and immediate operational efficiency. Their ability to swiftly assess financial systems, implement necessary changes, and provide strategic guidance allows companies, especially during transitional periods, to maintain stability and achieve their financial objectives.

Organizations looking to optimize their financial oversight should consider the strategic advantage of engaging interim CFOs to navigate complexities and foster growth. For more insights on leveraging financial expertise, visit www.fdcapital.co.uk to explore how interim solutions can elevate your businesss financial management.

Business

How to Cut Costs on Shipping to Amazon Warehouses – 2025 Update

Published

8 months agoon

June 16, 2025

Shipping products to Amazon FBA warehouses is a major expense for third-party sellers. Whether you’re shipping a single box via SPD (Small Parcel Delivery) or pallet loads through LTL/FTL (Less Than Truckload/Full Truckload), shipping costs can eat up 15% to 40% of your total margin if not carefully optimized.

In 2025, with higher fuel surcharges, regional delivery bottlenecks, and Amazon’s stricter FBA receiving policies, cutting shipping costs is no longer optional—it’s a necessity for profitability.

Checklist for Cutting Amazon FBA Shipping Costs

| Action | Benefit |

| Use Partnered Carriers | Save 30–70% on SPD/LTL rates |

| Consolidate into LTL when possible | Reduce per-unit cost and handling fees |

| Ship from prep centers near FCs | Shorten the last-mile distance |

| Use standard box/pallet dimensions | Avoid oversized penalties |

| Automate with FBA software tools | Reduce labor cost, avoid prep errors |

1. Choose the Right Shipping Method: SPD vs. LTL/FTL

Many sellers default to SPD because it’s familiar and easier to set up. But as your shipment volume grows, this method quickly becomes inefficient. If you’re sending multiple boxes regularly, switching to LTL or FTL can significantly lower your per-unit cost.

LTL is ideal for 1–4 pallets, while FTL becomes more economical once you’re shipping 20+ pallets. The larger and more frequent your shipments, the more you save through freight consolidation and pallet optimization.

| Shipping Method | Best For | Typical Volume | Cost Efficiency |

| SPD (Small Parcel) | Low-volume shipments (<150 lbs per box) | Under 10 boxes | Low to Moderate |

| LTL (Less Than Truckload) | Medium-volume shipments | 1–4 pallets | High for consolidated loads |

| FTL (Full Truckload) | Large shipments to one FC | 20+ pallets | Very high if volume allows |

Always run a side-by-side cost analysis between Amazon’s partnered LTL and SPD options for the same shipment. Even at lower volumes, LTL can beat SPD in cost-per-unit when handled correctly.

2. Optimize Box and Pallet Dimensions

Smartly stacked boxes and pallets in Amazon warehouses highlight how optimizing dimensions helps maximize space utilization

Dimensional weight pricing has become the standard for carriers, meaning your shipping bill depends as much on volume as on actual weight. Oversized packaging, under-filled boxes, or poorly stacked pallets all translate into wasted money.

Even minor changes to your box dimensions can cut down on shipping charges significantly. It’s especially important to standardize carton sizes across SKUs and ensure you’re getting the most efficient stackability when using LTL or FTL.

| Packaging Type | Cost Impact | Optimization Tip |

| Oversized Boxes | Higher per-unit cost + surcharges | Split items into smaller boxes |

| Inconsistent Sizes | Inefficient pallet use | Use standard cartons |

| Poor Pallet Stacking | May result in Amazon rejections | Follow Amazon’s FBA pallet guidelines |

A Freightos shipping case study found that by trimming box height by just 2 inches across 300 monthly units, one seller saved $420 in dimensional weight charges over 30 days.

3. Consolidate Shipments Strategically

Frequent small shipments often result in higher per-unit shipping costs, more carrier pickups, and a higher likelihood of fulfillment center delays. Consolidating multiple small shipments into a single, well-organized load saves on handling and often qualifies for better freight rates.

More importantly, Amazon prefers well-labeled, bulk deliveries over fragmented ones, which can

delay check-ins during peak seasons.

| Scenario | Estimated Monthly Shipping Cost | With Consolidation |

| 4 SPD shipments × 10 boxes | $900 | $540 |

| 1 LTL pallet shipment (same qty) | — | $480 |

If you’re using a prep center or 3PL, schedule shipments biweekly or monthly instead of weekly. Many centers will hold goods for a few extra days to help you consolidate at no added cost.

4. Use a Prep Center Near Amazon FCs

A prep center near Amazon warehouses ensures faster and more accurate processing of shipments ready for dispatch

Shipping across the country adds avoidable costs, especially if your inventory is already located closer to Amazon’s main fulfillment hubs, according to Dollan Prep Center. Working with a prep center within a short distance of Amazon’s major FCs helps you reduce last-mile freight charges, shorten delivery windows, and reduce potential delays during appointment scheduling.

This also increases the chances of faster check-ins and fewer rescheduling penalties.

| Top FC Regions | Benefits of Nearby Prep Centers |

| Dallas/Fort Worth, TX | Central location, multiple nearby Amazon FCs |

| Hebron, KY | Common FBA inbound point for East Coast sellers |

| Moreno Valley, CA | Ideal for West Coast imports from Asia |

| Allentown, PA | High Amazon FC density, fast East Coast distribution |

Relocating your prep and storage from the West Coast to Kentucky or Ohio can reduce per-pallet shipping costs by 20–30%, especially for sellers distributing nationwide.

5. Leverage Amazon’s Partnered Carrier Program

Amazon offers discounted rates through its partnered carrier program, which includes both UPS for SPD shipments and several freight providers for LTL and FTL loads. These discounts are only available if you create shipments directly through Seller Central and use Amazon’s pre-approved carriers.

In most cases, Amazon’s partnered rates beat outside quotes, even those from negotiated commercial accounts.

| Service | Estimated Discount |

| Partnered SPD (UPS) | 30%–50% |

| Partnered LTL (XPO, CEVA, etc.) | 40%–70% |

While you must comply with Amazon’s strict packaging and labeling requirements to access these rates, the savings are substantial, l—especially for high-volume sellers or those regularly shipping to distant FCs.

6. Reduce Rejected Shipments with Better Labeling and Packing

Neatly stacked boxes in Amazon warehouses demonstrate strategies to reduce rejected shipments and improve delivery efficiency

FBA rejections are costly and often entirely avoidable. If your shipment arrives with incorrect labels, mixed SKUs, damaged boxes, or non-standard pallets, Amazon may either reject the shipment or charge you additional fees for correction.

These mistakes lead to delays, inventory miscounts, and wasted freight costs. Proper prep practices—including double-checking barcode placements and securely packing all cartons—go a long way in avoiding financial hits.

| Mistake | Possible Charge |

| Wrong label placement | $0.20–$0.30 per unit |

| Unscannable barcode | $0.15–$0.40 per unit |

| Rejected pallet | Full reshipment cost |

Based on Amazon seller reports, approximately 1 in 5 shipments that result in receiving delays are traced back to labeling or prep errors, ot transport problems.

7. Compare 3PL and Freight Forwarder Rates

Freight pricing varies widely depending on your route, volume, and carrier network. Many sellers overlook potential savings by sticking with default options like Amazon Partnered LTL when they could secure lower rates via third-party logistics (3PL) providers or freight brokers.

For international shipments, especially from Asia, consider FBA-friendly freight forwarders who understand Amazon labeling and delivery protocols.

| Shipping Scenario | Amazon Partnered Rate | 3PL Broker Rate | Savings Potential |

| 3 pallets to California FC | $620 | $520 | ~$100 (16%) |

| Full container from China | $2,400 | $1,800 | ~$600 (25%) |

Always confirm that your 3PL or freight broker can handle Amazon’s strict delivery appointments and ASN documentation. Mishandled deliveries can delay check-in by days or even weeks.

8. Use Software to Automate and Optimize Shipping

Managing logistics manually might work at a small scale, but as your operation grows, automation is critical. FBA-compatible software can help you generate labels, track freight costs, schedule restocks, and reduce prep errors.

Most tools also offer data dashboards that allow you to compare historical shipping costs and identify which products are the most expensive to move.

| Tool | Functionality |

| InventoryLab | Shipment creation, cost tracking, and label printing |

| RestockPro | Restocking suggestions and forecasting |

| ShipStation | Multi-carrier shipping rate comparisons |

| Sellerboard | Profit analysis, including logistics cost modeling |

Automating shipment creation and integrating freight cost visibility into your inventory management can help reduce administrative time by 20–30% and prevent avoidable prep center errors.

9. Negotiate Better Terms with Your Prep or Freight Providers

Shipping costs are not always fixed. If you’re consistently sending volume to FBA, you have leverage. Many prep centers, LTL brokers, and freight forwarders offer volume discounts, flat fees per pallet, or reduced storage costs if you ask.

Review your past 3–6 months of shipping data, calculate your average pallet count, and initiate a negotiation with your vendors.

Tip: Sellers averaging 10+ pallets per month can often secure flat monthly pallet rates, discounted receiving, or free shrink-wrapping—terms that reduce your cost per unit long term.

10. Eliminate Dead Weight: Audit Unprofitable Shipments

A focus on eliminating dead weight in Amazon warehouses leads to lighter, more cost-effective shipments

Not every product is worth shipping. It’s easy to fall into the trap of sending every piece of inventory to FBA, regardless of sales velocity or margin. Always review your SKU profitability before creating a shipment.

If a product yields less than $5 net profit after shipping and FBA fees, it may not be worth warehousing, especially if it ties up cash flow or increases long-term storage fees.

Sellers who regularly audit their shipping loads and purge underperforming inventory can reduce overall FBA shipping costs by 15–25%, according to Helium 10 seller data from Q4 2024.

Conclusion

Shipping costs are one of the easiest areas to improve once you understand the variables that impact pricing, from carton sizes to shipping method selection, from software automation to vendor negotiation.

In 2025, sellers who optimize these components can see thousands in annual savings and increase their margins without selling a single extra unit. Whether you’re operating at 500 units per month or 50,000, controlling your logistics pipeline will separate your business from competitors who let costs run unchecked.

Business

Post-Purchase Customer Experience – Why It’s the Key to Retention and Loyalty

Published

1 year agoon

February 6, 2025

In today’s fiercely competitive marketplace, securing a sale is just the beginning of the customer journey, not the end. Post-purchase customer experience has emerged as a pivotal aspect of not only retaining clients but also building unwavering loyalty.

Once the transaction is completed, a new chapter unfolds—one that can either transform a one-time buyer into a lifelong advocate or reduce them to just another statistic in the sea of disengaged consumers. Every interaction a customer has after the purchase, from personalized follow-ups to seamless customer support, plays a crucial role in shaping their perception of your brand.

As the dust settles on their initial decision to buy, it’s the ongoing experiences that will ultimately determine whether they return for more or drift away into the clutches of competitors. Understanding and optimizing this journey is not merely an option anymore; it’s a necessity for businesses striving to cultivate lasting relationships in a world where choices abound.

The Path to Loyalty: How Post-Purchase Experience Shapes Customer Relationships

Source: reverselogix.com

The journey to fostering customer loyalty begins long after the initial purchase is made; it is intricately woven into the fabric of the post-purchase experience. Picture this: a customer who eagerly anticipates their delivery, receiving a thoughtful follow-up email that not only confirms shipment but also includes tips for maximizing the product’s use—this simple gesture cultivates a sense of connection.

Afterward, a timely survey asking for feedback demonstrates that their voice matters, transforming a transactional relationship into a dialogue. Each element, from personalized recommendations based on their purchase history to dedicated customer support, deepens trust and enhances the emotional bond.

In this ever-competitive landscape, understanding that retention hinges not on the initial sale, but on the entire journey afterwards, can unlock the secret to creating lifelong advocates for your brand.

Beyond the Sale: The Critical Role of Aftercare in Customer Retention

Source: globalresponse.com

In the whirlwind of commerce, where transactions often take center stage, one critical aspect frequently slips through the cracks: aftercare. This pivotal phase begins the moment a customer clicks “confirm” on their order, extending well beyond the point of sale.

It’s not merely a follow-up; it’s a commitment to nurturing the relationship, a chance to reinforce the connection established during their buying journey. Think of aftercare as the secret sauce of customer loyalty—personalized messages, helpful tips, and timely support can transform an ordinary experience into an extraordinary one.

Customers who feel valued and supported are more likely to return, not just for the products they cherish but for the community and service that accompany them. In a landscape flooded with choices, businesses that prioritize aftercare don’t just sell products; they cultivate loyalty, turning one-time buyers into lifelong advocates.

Conclusion

Source: youngurbanproject.com

In conclusion, the post-purchase customer experience is a critical pillar in fostering retention and loyalty among consumers. By understanding and enhancing this stage of the customer journey, businesses can build lasting relationships that go beyond a single transaction.

Effective post-purchase marketing not only reinforces the value of the initial purchase but also encourages repeat business through personalized communication and ongoing engagement. As companies strive to differentiate themselves in a competitive landscape, prioritizing the post-purchase experience will prove essential in transforming customers into brand advocates, ultimately driving sustainable growth and long-term success.

Order Tracking Experience Optimization For DTC Brands

How Much Money A Travel Agent Can Earn Today

High End Business Dinner Venues In Munich City Center

Game On: North Texas is a ‘Technology Entertainment Concept ‘Paradise.

Cannondale Information: All-new Topstone Carbon gravel bicycle unveiled.

EU takes steps to legislate sustainable fashion. It will work.

Trending

-

Entertainment4 years ago

Entertainment4 years agoGame On: North Texas is a ‘Technology Entertainment Concept ‘Paradise.

-

Sports4 years ago

Sports4 years agoCannondale Information: All-new Topstone Carbon gravel bicycle unveiled.

-

Fashion4 years ago

Fashion4 years agoEU takes steps to legislate sustainable fashion. It will work.

-

Business4 years ago

Business4 years agoCustomer Experience Innovation: The New Battlefield For Businesses.

-

Fashion4 years ago

Fashion4 years agoDubai Design District welcomes leading Polish designers to the world-class fashion community.

-

Business4 years ago

Business4 years agoThe Defence industry supports hundreds of UK jobs and business.

-

Entertainment3 years ago

Entertainment3 years agoWhat is Nudekay, and How can I create it?

-

Business3 years ago

Business3 years agoA Guide To Anti-Money Laundering For Your Business.